Abstract

ddPCR is a method to quantify absolute copy numbers of a target.

Materials

Reagents

- QX200 EvaGreen Digital PCR Supermix

- QX200 Droplet Generation Oil

- DG8 Cartridges

- DG8 Gaskets

Equipment

- QX200 Droplet Generator and Reader

- 96 well PCR

- 50 ul Multichannel, Rannin tip compatible.

- Plate Sealer

Primer Design

Widely accepted quantitative PCR (qPCR) design guidelines apply to ddPCR primer design. Important criteria for single primers include melting temperature (Tm), length, base composition, and GC content. Ensure that paired primers do not exhibit significant complementarity between 3′ ends because this can result in primer-dimers.

- Plan to amplify a 60–200 bp product

- Avoid regions that have secondary structure when possible, the ΔG should be > –9.0 kcal/mole

- Choose a region that, ideally, has a GC content of 40–60%

- Strive for a Tm between 60 and 65°C. Ideally 62C. Probes should have a Tm 6C higher than the primers

- Use Primer3 or BLAST-primer

Procedure for Evagreen DDPCR Reactions

Notes: Reactions must be multiples of 8. Use filter tips when possible.

1. Prepare dilutions of the samples. The dynamic range of the QX200 is 1-100,000 copies per 20ul reaction on a good day. Using a qubit, estimate the copy number of the target and prepare the dilution. Or if the samples are to dilute to measure, but similar in concentration, run the dilutions of a single sample to hone in on a dilution. Intact eukaryotic genomes should be ≤66 ng per 20 μl reaction. Otherwise, a restriction digest might be necessary.

2. Thaw supermix on ice. And vortex vigorously.

3. Optional. If the target is genomic DNA, over 66ng of input or a copy number assay, Digestion is recommended. Pick a restriction enzyme with a small cut size and low salt, that targets outside your amplicon.

4. Prepare reaction. It is critical to have exact volumes for accurate quantification. Thus the over preparation of the reaction mix. I recommend adding 2.25ul of sample in step 7, as it makes downstream calculations easy.

| Component |

μl per 25μl sample |

μl for 8 25μl samples |

Final Conc |

| 2X SuperMix |

12.5 |

100 |

1x |

| Primers 100μM each |

0.025 to 0.0625 |

0.2 to 0.5 |

100nM to 250nM |

| Restriction Enzyme |

? |

? |

2-5 units |

| Sample (don’t add yet) |

? |

? |

1-100k copies |

| H20 |

=12.5 – (Primer*2+RE+Samp) |

=100 – (Primer*2+RE+Samp) |

|

5. Vortex the hell out of the reaction mix. And then vortex it some more. Spin briefly.

6. Dispense a volume that is equal to 22.5μl – Samp μl into locking PCR strip tubes.

7. Add your samples to the tubes.

8. Vortex the tubes at full speed till your hands go numb or the vortexer catches fire, whichever occurs first. Spin briefly.

9. Place a new DG8 cartridge in the holder. Using the Rainin p20 add 20ul of the samples in to the sample row, avoid bubbles, place the tips on the bottom corner of the well and tilt the pipette slightly, ~15°. Slowly dispense. Don’t go past the first stop. If for any reason you are unable to transfer exactly 20μl for a sample, take an amount you can and record it.

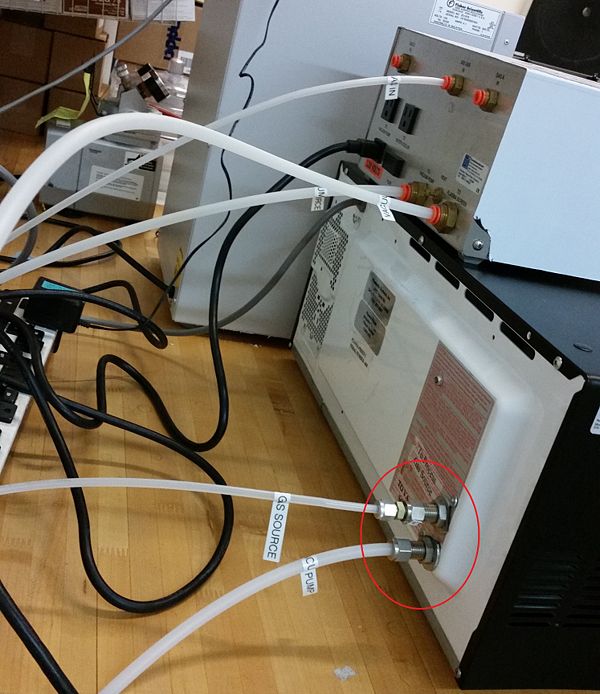

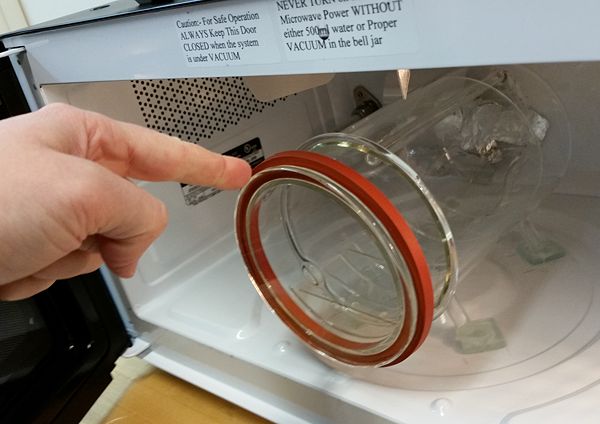

10. Place 70μl of Droplet Generation Oil for EvaGreen in the oil wells. Place a new red gasket over the hooks and place the assembly in the droplet generator. Press the button and wait. If for any reason the entire 20μl of sample is not consumed, measure the remaining amount and record it.

11. Using the Rainin L-50 with green box tips set to 40μl. Slowly place the tips into the bottom corner of the well at a 45° tilt. Slowly and smoothly draw the droplets, don’t aspirate air. Slowly deposit droplets into a column of a semi/unskirted heat sealable 96 well plate.

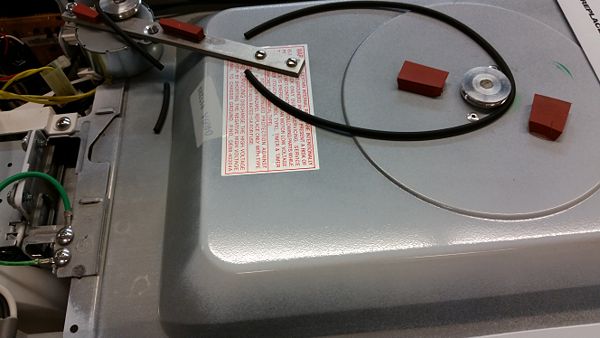

12. Carefully carry the plate to the heat sealer, and seal with a pierceable foil.

13. Carefully carry the plate to the PCR. And run the reaction as follows

| Cycling Step |

Temperature,C |

Time |

Ramp Rate |

Number of Cycles |

| Enzyme Activation |

95 |

5 Min |

2C/sec |

1 |

| Denaturation |

95 |

30 Sec |

40 |

| Annealing/Extension |

60 |

1 Min |

40 |

| Signal Stabilization |

4 |

5 Min |

1 |

| 90 |

5 Min |

1 |

| Hold |

4 |

Inf |

1 |

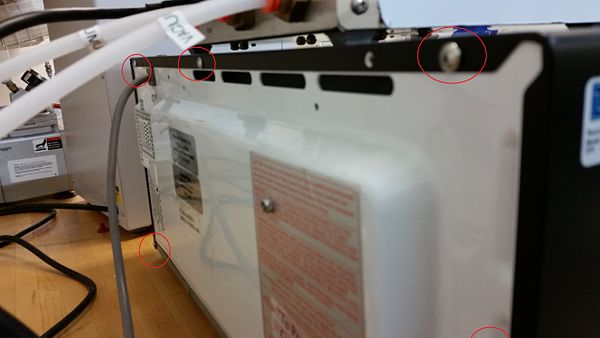

14. After thermal cycling, place the sealed 96-well plate in the QX200 Droplet Reader.

Data Acquisition and Analysis

1. Open QuantaSoft TM Software to set up a new plate layout according to the experimental design.

2. Under Setup, double click on a well in the plate layout to open the Well Editor dialog box.

3. Designate the sample name, experiment type, QX200 ddPCR EvaGreen Supermix as the supermix type, target name, and target type: Ch1 for FAM.

4. Select Apply to load the wells and when finished, select OK.

5. Once the plate layout is complete, select Run to begin the droplet reading process. Select EvaGreen as the dye set used and run options when prompted.

6. After data acquisition, select samples in the well selector under Analyze. Examine the automatic thresholding applied to the 1-D amplitude data and, if necessary, set thresholds or clusters manually.

7. The concentration reported is copies/μl of a 20ul ddPCR reaction. If using 2.25ul of sample in step 7, the reported concentration is 1:10 dilution of the original.

Procedure for Probe DDPCR Reactions

Notes: Reactions must be multiples of 8. Use filter tips when possible.

1. Prepare dilutions of the samples. The dynamic range of the QX200 is 1-100,000 copies per 20ul reaction on a good day. Using a qubit, estimate the copy number of the target and prepare the dilution. Or if the samples are to dilute to measure, but similar in concentration, run the dilutions of a single sample to hone in on a dilution.

2. Thaw supermix on ice. And vortex vigorously.

3. Optional. If the target is genomic DNA, over 66ng of input or a copy number assay, Digestion is recommended. Pick a restriction enzyme with a small cut size and low salt, that targets outside your amplicon.

4. Prepare reaction. It is critical to have exact volumes for accurate quantification. Thus the over preparation of the reaction mix. I recommend adding 2.25ul of sample in step 7, as it makes downstream calculations easy.

| Component |

μl per 25μl sample |

μl for 8 25μl samples |

Final Conc |

| 2X SuperMix |

12.5 |

100 |

1x |

| Primers 100μM each |

0.225 |

1.8 |

900nM |

| Probes 100μM each |

0.0625 |

0.5 |

250nM |

| Restriction Enzyme |

? |

? |

2-5 units |

| Sample (don’t add yet) |

? |

? |

1-100k copies |

| H20 |

=12.5 – (Primer*?+Probe*?+RE+Samp) |

=100 – (Primer*?+Probe*?+RE+Samp) |

|

5. Vortex the hell out of the reaction mix. And then vortex it some more. Spin briefly.

6. Dispense a volume that is equal to 22.5μl – Samp μl into locking PCR strip tubes.

7. Add your samples to the tubes.

8. Vortex the tubes at full speed till your hands go numb or the vortexer catches fire, whichever occurs first. Spin briefly.

9. Place a new DG8 cartridge in the holder. Using the Rainin p20 add 20ul of the samples in to the sample row, avoid bubbles, place the tips on the bottom corner of the well and tilt the pipette slightly, ~15°. Slowly dispense. Don’t go past the first stop. If for any reason you are unable to transfer exactly 20μl for a sample, take an amount you can and record it.

10. Place 70μl of Droplet Generation Oil for probes in the oil wells. Place a new red gasket over the hooks and place the assembly in the droplet generator. Press the button and wait. If for any reason the entire 20μl of sample is not consumed, measure the remaining amount and record it.

11. Using the Rainin L-50 with green box tips set to 40μl. Slowly place the tips into the bottom corner of the well at a 45° tilt. Slowly and smoothly draw the droplets, don’t aspirate air. Slowly deposit droplets into a column of a semi/unskirted heat sealable 96 well plate.

12. Carefully carry the plate to the heat sealer, and seal with a pierceable foil.

13. Carefully carry the plate to the PCR. And run the reaction as follows

| Cycling Step |

Temperature,C |

Time |

Ramp Rate |

Number of Cycles |

| Enzyme Activation |

95 |

5 Min |

2C/sec |

1 |

| Denaturation |

94 |

30 Sec |

40 |

| Annealing/Extension |

60 |

1 Min |

40 |

| Signal Stabilization |

4 |

5 Min |

1 |

| 90 |

5 Min |

1 |

| Hold |

4 |

Inf |

1 |

14. After thermal cycling, place the sealed 96-well plate in the QX200 Droplet Reader.

Data Acquisition and Analysis

1. Open QuantaSoft TM Software to set up a new plate layout according to the experimental design.

2. Under Setup, double click on a well in the plate layout to open the Well Editor dialog box.

3. Designate the sample name, experiment type, ddPCR Supermix for Probes as the supermix type, target name, and target type: Ch1 for FAM. Ch2 for HEX/VIC

5. Select Apply to load the wells and when finished, select OK.

6. Once the plate layout is complete, select Run to begin the droplet reading process. Select the appropriate dye set used and run options when prompted.

7. After data acquisition, select samples in the well selector under Analyze. Examine the automatic thresholding applied to the 1-D/2-D amplitude data and, if necessary, set thresholds or clusters manually.

8. The concentration reported is copies/μl of a 20ul ddPCR reaction. If using 2.25ul of sample in step 7, the reported concentration is 1:10 dilution of the original.